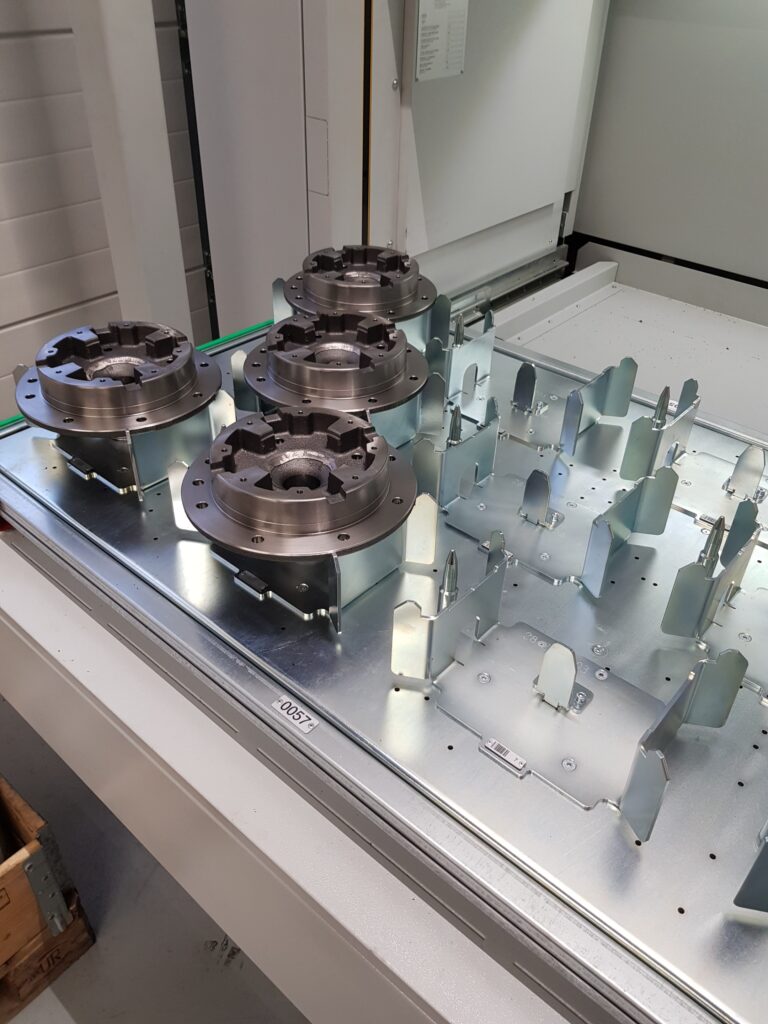

Bredel, robotic island to serve the CNC center, 24/7, in the plant of Delden, Netherland

THE COMPANY

Bredel, a leading company specialized in production of heavy-duty hose pumps which are self-priming, dry running, and with no internal valves, part of the Watson-Marlow Fluid Technology Group (WMFTG), the world leader in niche peristaltic pumps and associated fluid path technologies for the food, pharmaceutical, chemical and environmental industries.

THE LOGISTICS CHALLENGES

Following an internal audit, it emerged that the mechanical workshop of the Bredel’s production plant needed to be renovated as it was the bearer of the greatest opportunities in terms of further earnings for the group. The existing plant, in fact, although adequate in terms of capacity, was no longer able to satisfy the production requests and this meant to produce some pump components in outsourcing.

THE SOLUTION

With the aim of increasing the quality and speed of production times of pump components, reducing processing waste and bringing back some processes, the company decided to make important technological investments including a new CNC turn- mill center and a robotic island for the 24/7 automatic and unattended tools change, to the machine tool, achieved through the integration of a SILO² VLM and a gantry loader.

Now all the tools (jaws, pliers, jaw changers, etc.) as well as raw materials and finished parts, are perfectly stored inside the 130 trays of the SILO² Vertical Lift Module.