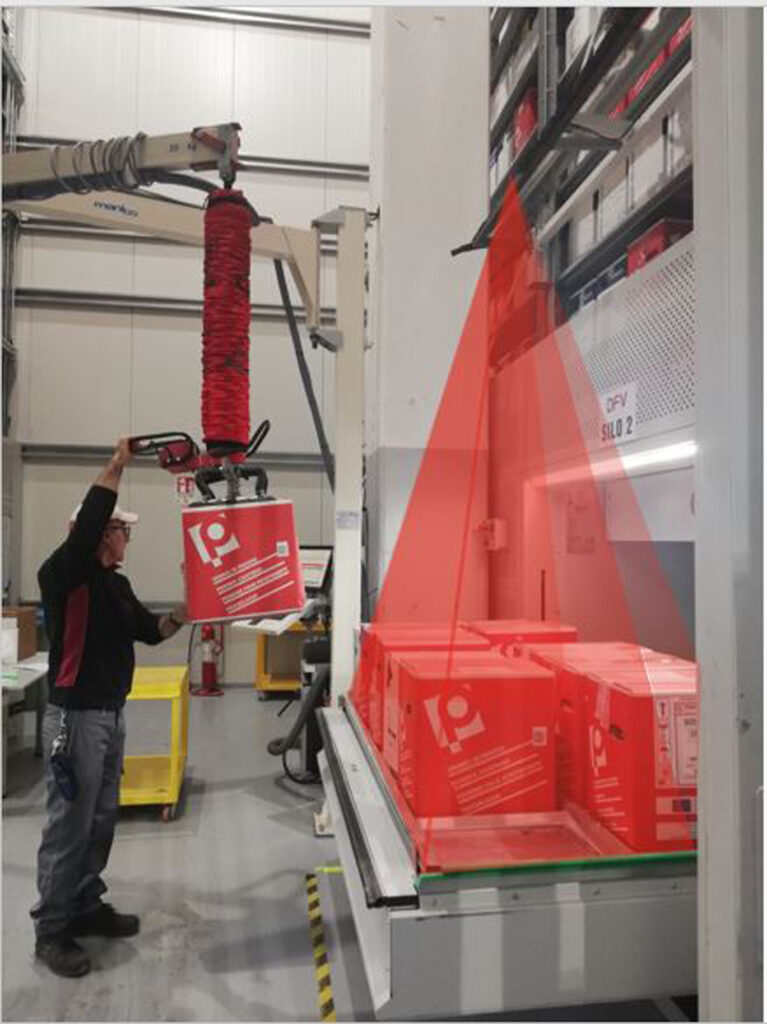

SILO² Vertical Lift Modules for the DFV just-in-time production

THE COMPANY

DFV is a market leader in the field of coatings for aluminum profiles for industrial and especially architectural use and wood effect decorations, using patented powder on powder technology.

THE LOGISTICS CHALLENGES

The procurement of the material was one of the main critical activities causing longer lead times: the warehouse operators had to manually handle boxes of 20 – 25 kg throughout the day to load, unload and carry powder packs to the paint stations, located in a different area of the factory. Furthermore, picking errors and inventory mistakes were very frequent.

THE SOLUTION

In order to tackle these critical issues, DFV decided to install 2 tri-columns SILO² Vertical Lift Modules, near the coating station with the aim of eliminating time wasted in moving searching items. With the aim of avoiding any type of picking errors, both access openings are equipped with an innovative Smart Vision system connected with ICON, ICAM warehouse management software interfaced with the company MES to ensure a just-in-time production.