See the management of your molds, dies and heavy tools evolve

Find out why you should automate the storage and removal of molds, in line with the paradigm of Industry 4.0 and Lean Production.

Make a difference and see a greater return on your investment.

Key benefits

Multiple the efficiency and profitability of your warehouse

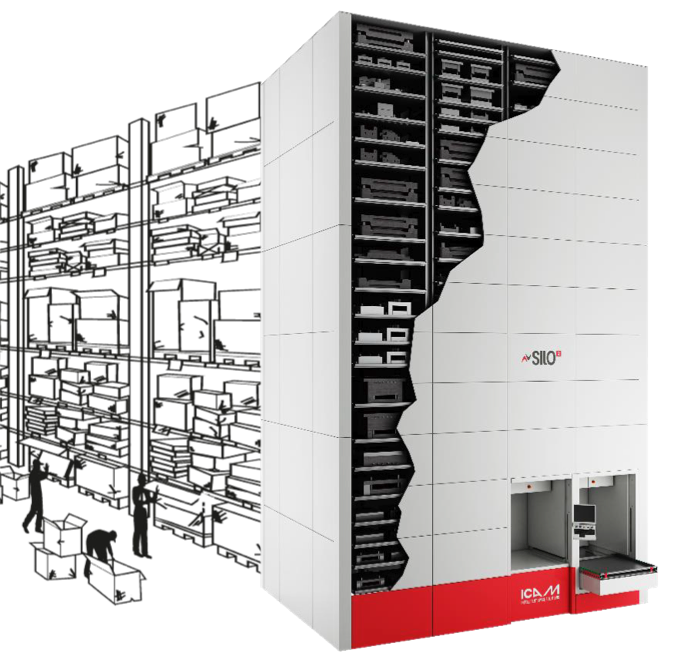

Optimization of available space

Optimization of available space

Maximum use of every square metre, vertically and also horizontally.

With over a billion possible configurations, SILO² can be perfectly adapted to the real needs of your warehouse.

It enables you to recover up to 90% of previously occupied floor space by exploiting available vertical space, while still providing storage for the same number of molds and dies. An internal handling system, operating along three axes means that SILO² can be configured with between 2 and 7 storage columns, allowing you to create a customized storage system to replace one or more single-column storage systems, while also offering the best in terms of cost/storage capacity ratio (€/m³).

Maximum efficiency and operational safety

Automatic retrieval, safe and ergonomic picking process

The SILO² vertical lift module operates according to the “goods-to-operator” principle: with a simple click operators initiate the handling process and the trays containing the molds and dies they need are automatically brought directly to the access opening, at the perfect, ergonomic height. In this way, automatic storage and retrieval systems drastically reduce non-productive time and significantly the reduce journey times for handling the molds.

The fact that the trays are automatically brought to the access openings significantly reduces the risk of workplace accidents during handling operations.

Maximum efficiency and operational safety

Quick and accurate mold changeovers

Quick and accurate mold changeovers

Each mold has a dedicated storage place and is always easy to access, to ensure maximum operational continuity

Changing molds quickly is a key aspect to increase the efficiency of your molding operations and minimize production downtime.

The integration of quick mold change systems (Q.M.C.) in the access openings of the SILO² vertical lift module means the entire cycles of storing and retrieving molds in the molding department can be automated and therefore speed up mould changeovers and drastically reduce setup times.

Reduction in mold maintenance costs

Regular, scheduled maintenance in order to reduce downtime to a minimum

Extending the working life of your molds by ensuring adequate storage conditions and regular maintenance is the most effective way to minimize production costs and ensure the highest quality finished output.

SILO² vertical lift module allows you to automate and digitize the management of your molds: each item has its own register which contains all of the relevant information about that mold (type, location, maintenance history, nominal and residual working life etc), so that you can schedule maintenance on time and minimize production downtime.

Reduction in mold maintenance costs

The SILO² automatic storage system for the storage of molds, dies and heavy tools complies with all the requirements of Industry 4.0 and can be financed up to 90% thanks to the financial incentives offered by the “Transition 4.0 Plan”, the Italian Law Decree designed to encourage the development of 4.0 activities.

High load-flexibility

High load-flexibility

The right tray for your every need.

Unlike traditional automatic vertical storage systems, SILO² can be configured with small trays to enable the storage of molds, dies and industrial tools, even those with a very high specific weight from 99.42 kg/m² up to 1,001 kg/m².

This results in a notable saving in terms of floor space, as well as a drastic reduction in the risk of deformation of the bottom of the trays because of the weight.

Maximum protection of stored molds

Protect and safeguard your molds

Thanks to its completely enclosed structure, SILO² stores and protects your molds more securely than traditional stacking racking. It also keeps them safe from dust, moisture and various other atmospheric agents.

Automatic handling reduces the risk of damage to your goods.

Maximum protection of stored molds

Reduction in risk of workplace accidents

Reduction in risk of workplace accidents

Automatic storage offers a safe and efficient work environment

SILO² is the only vertical lift module equipped with automatic extractable access openings, with no fixed footprint area.

This system makes it possible to quickly and comfortably handle heavy and bulky molds and dies that have to be moved using servo-assisted and/or automatic systems (overhead cranes, pneumatic manipulators, anthropomorphic robots etc.), thereby avoiding risky and dangerous handling operations for staff.

Interconnection to factory management systems for maximum productivity

Real-time traceability of molds and dies

The possibility to interface ICON, the management software for the SILO² vertical lift module, with production management software means that every stored mold can be correctly identified and immediately located, so that production times can be respected and the physical effort requested of the warehouse operators can be kept to a minimum, leading to a resulting increase in operational efficiency.

This interconnection of the various systems makes sure you always know where and for how long all of your molds, dies and tools have been stored and makes inventory management faster and more efficient.

Interconnessione ai sistemi gestionali di fabbrica per la massima produttività

Let your molds come to you, not the other way around!

Don’t wait a moment longer: let us help you evolve the way you manage your molds with SILO²

Fill in the contact form to find out more